Dalphin Drinks,

natural purity in bottles

Production Process

All plastic bottles are blown for bottling. Before these bottles to the filling process are offered, they will all be inspected visually. This is to prevent bad or contaminated bottles are used.

The approved bottles are offered to a fully automated washing machine. This cleans the bottles, then rinsed and disinfected.

Afterwards, the bottles are filled and hermetically sealed with a Cap. After the filling process, the bottles are transported to the warehouses. From there it is distributed to the customer.

The fully computer-controlled bottling plant meets the highest requirements in terms of hygiene.

The approved bottles are offered to a fully automated washing machine. This cleans the bottles, then rinsed and disinfected.

Afterwards, the bottles are filled and hermetically sealed with a Cap. After the filling process, the bottles are transported to the warehouses. From there it is distributed to the customer.

The fully computer-controlled bottling plant meets the highest requirements in terms of hygiene.

1.8 million liter per day.

The bottling plant has a large number of production lines that a large portion of the daily production of more than 1.8 million liter of mineral water processed.

Is a own label something for you?

You too can use the professional production line for bottling under your own label. Dalphin is a ' Turn Key ' bottling plant where you can involve your own label drinks without problems. ' Turn Key' means; a single point of contact for the entire production. Dalphin serves and accompanies the entire production from the idea through distribution.

Our companies

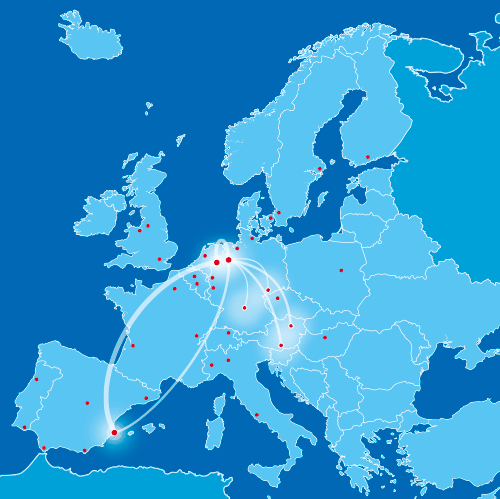

The headquarters of the Dalphin International Group is located in Winterswijk, Holland amidst the beautiful nature of the Achterhoek.

Our German sales office is located in the province of Nordrhein-Westfalen, centrally located in the heart of Europe.

In Spain we have a sales office since 2012, it is located in the beautiful province of Alicante.

Our German sales office is located in the province of Nordrhein-Westfalen, centrally located in the heart of Europe.

In Spain we have a sales office since 2012, it is located in the beautiful province of Alicante.